The Making of Hachimonjiya Original NOBLE NOTE “Hatsuyuki”

LIFE x Hachimonjiya's Original NOBLE NOTE.

Thanks to all of you, various people have purchased our products at stores, Online shopping, and at Events!

Thank you! !

Life's Notebook binding Factory

Last fall, I was kindly invited by LIFE to visit their notebook manufacturing site.

Ordinary notebooks are bound by a method called "perfect binding," in which the spine of the paper is glued together.

4 bundles of 25 sheets are sewn together with thread, and the bindings are reinforced with cloth tape.

It is durable, and even with 100 sheets of paper, it does not fall apart.

How is that characteristically thick notebook, often referred to as a "four-book combination", made? I will show you that today.

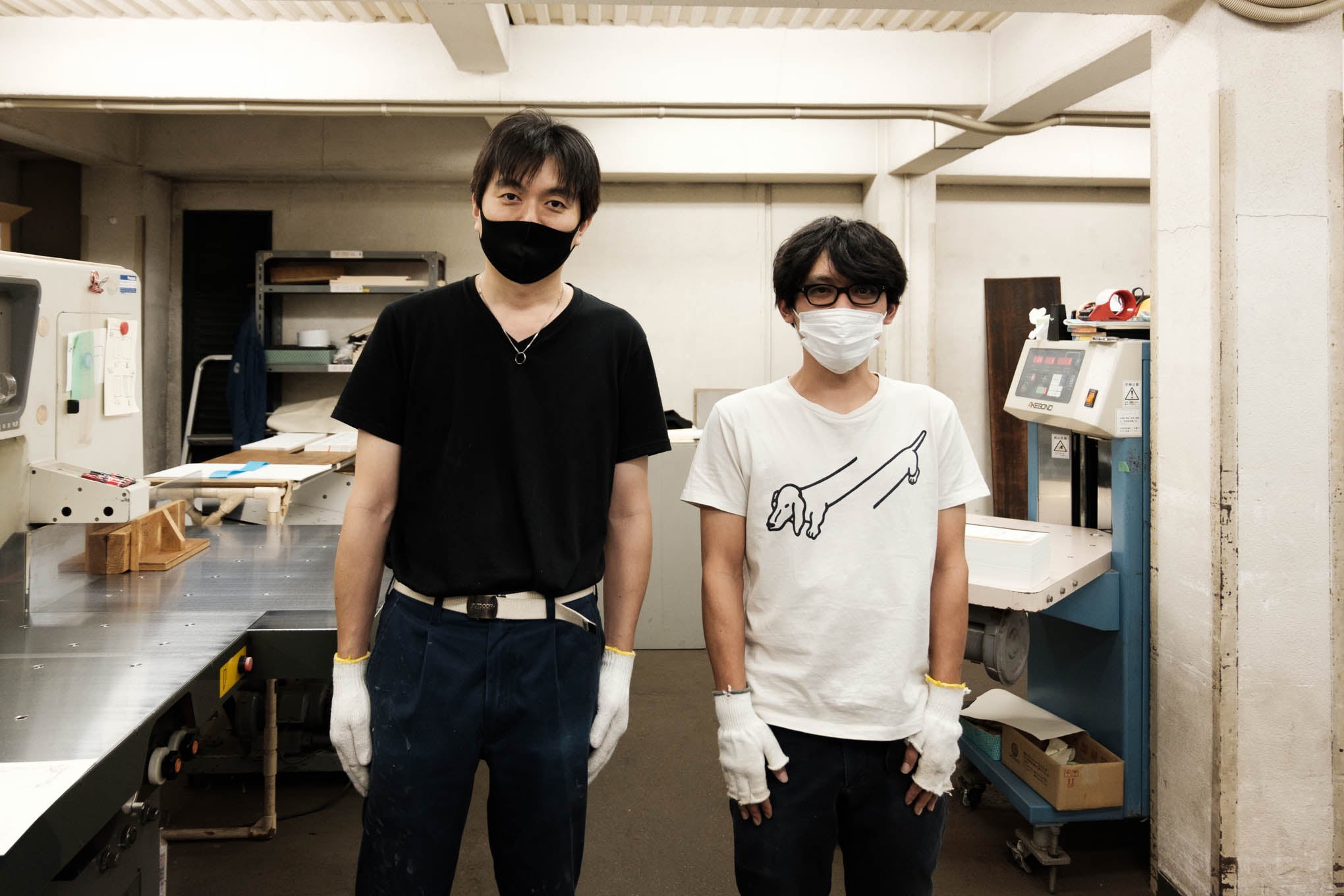

Mr. Nagayama (left) and Mr. Yamada (right), who mainly guide and explain.

Mr. Kurata (unfortunately absent), who is also a skilled master, works on the notebook as a three-person system.

Cutting

The Noble Note's text paper is an original "L Writing Paper" made from carefully selected raw materials.

This high-quality writing paper features a textured texture, smooth writing comfort, and little ink bleeding or bleed-through.

The "white" paper used for "Hatsuyuki" is finished so that the gradation of the ink stands out and sharp colors are produced.

Below is what is called a "printed book" that arrived in a rush from the printing company. It is the base of the notebook.

This is the first state. 2 front and back covers, 8 pages of text paper.

The large sheets of printed paper are cut together by a paper cutting machine for each notebook size.

Count (number of pieces)

Behind Mr. Nagayama, Mr. Yamada is in the next process.

A bundle of cut text paper is set in a machine called a number machine, and a green partition is inserted every 25 sheets.

This 25 sheet division becomes one bundle of notebooks.

Gathering

The work of sandwiching the front and back covers every 25 sheets.

13 pages of main text, cover, 25 pages of main text, front cover, 25 pages of main text (same below) … 12 pages of main text, 13 pages of main text, back cover, 25 pages of main text, back cover, 25 pages of main text Sheets (same below) ...... 12 sheets of text, and so on.

I made several bundles of "text 13 sheets, front cover, text 12 sheets" and "text 13 sheets, back cover, text 12 sheets", and these two bundles make up one notebook. It's also a pin.

Mr. Yokoyama from the management department and Mr. Ono from the sales department, who were also present, were asked to explain in turn, but my lack of understanding made the situation extremely chaotic.

The stack of text with the front cover and the stack of text with the back cover in between are distinguished by the color of the marker.

Sewing machine binding

Bind the front and back covers and the main text with an industrial sewing machine that sews a thick tent (!).

This is just like craftsmanship, sewing the center part of the paper bundle one after another.

At this stage, the left and right pages are not yet divided, but this stitch line will be the page division (fold) in the later process.

Mr. Yamada is currently in charge of this work, and there are times when he spends a whole day working on this.

It seems that the sewing machine is also customized for this work. Or taping is amazing ... ....

Folding

Fold the perforated stack of paper so that the cover is facing out.

This folding machine is the oldest of all the equipment here, and from the looks of it, it looks dignified (and the operating sound was also the most self-assertive...).

Firmly fold it in two from the middle (the sewn part).

After going through this process, it looks like a notebook.

I could see a little bit of the finished product.

Press ~ Sleep

Press the stitched spine flat.

Upper, before pressing, lower, after pressing.

Markers shown in the collating process.

In addition, put a weight on the stack of notebooks and let them rest overnight.

I can't just say, "Well, let's finish today and have a drink from now on?"

Gluing ~ Peeling off

Apply glue, attach thin paper, and reinforce the spine.

When the notebooks are completely dry, separate the stacked notebooks into 2 bundles of 4 stacks (100 sheets) each with a kitchen knife.

Mr. Yamada suddenly asked, "Would you like to try it?"

Originally, this kind of thing is a piece of crap, so it can't be cut cleanly at all.

I received a cold voice saying, "I will deliver this too~", so if the bottom of the back cloth is strangely bumpy, it will be my fault (I will buy it, please contact me).

Cloth paste

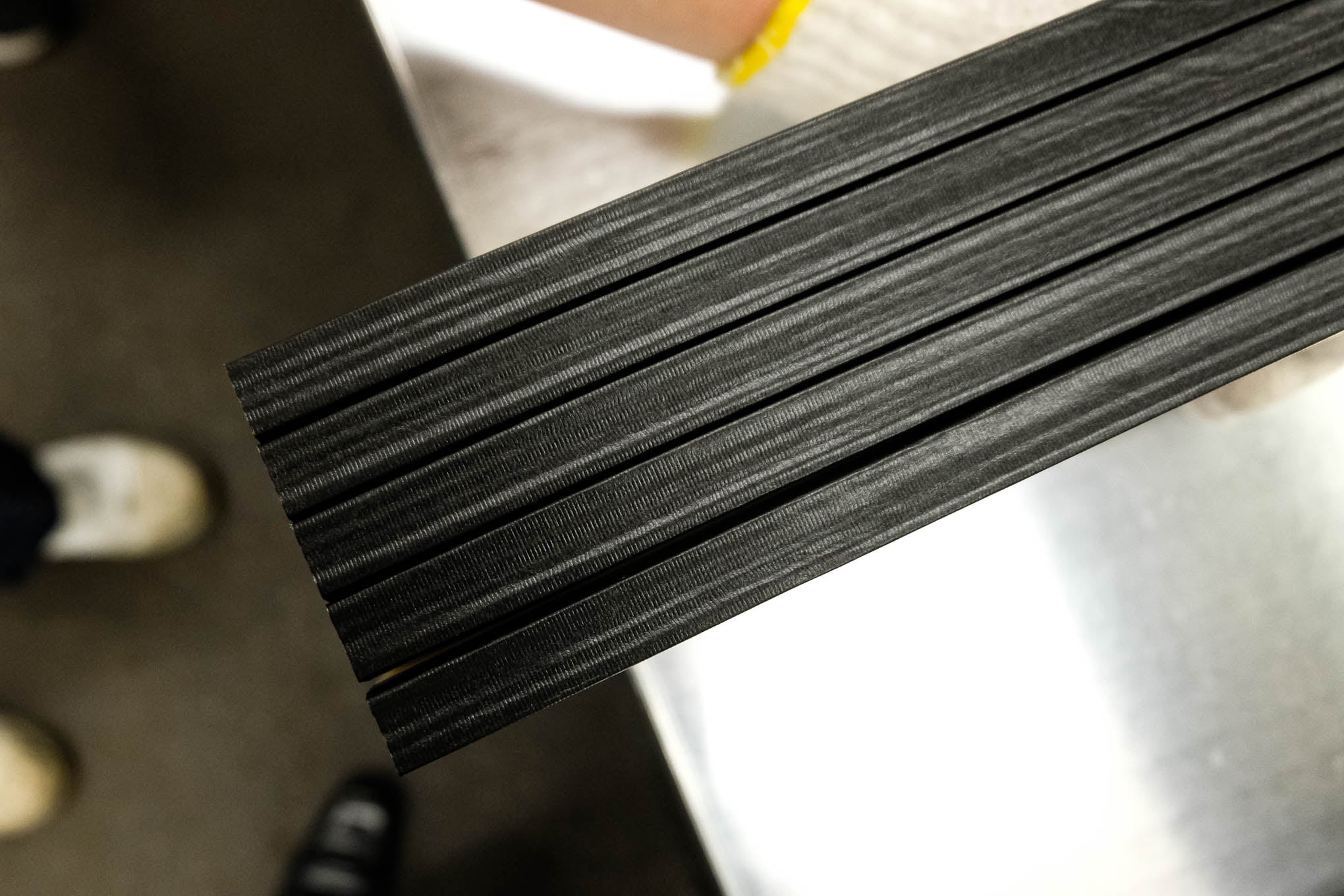

A cloth (black paper tape) is pasted on the bound part (the spine of the notebook).

The cloth used in Noble Note has a durable and luxurious pattern called "cloud".

Apply glue (the white part circulating with the roller) to the cloth.

In the center, the belt-like thing is cloth, and the thing sandwiched between them is a notebook ( I apologize for the unclear picture).

As the notebook is passed through the machine, the cloth attached to it is also pulled and drawn out one after another.

It goes up like this in units of two.

Finish cutting

Finally, it is put through the cutting machine again and finished in the shape of a notebook.

Divide into two halves and cut into strips.

Cut off the three sides (top, bottom, edge) other than the spine (three-sided trimming), and you 're done!

Beautiful back finish. In order to avoid cracks and distortions in the cloth, it is carefully cut in several steps.

After visiting

According to Mr. Nagayama, the three-way cutting in the above process is also called "removing makeup."

From there, it left an impression on me that the name of each part of the notebook had something to do with the human body. increase.

It may be because I witnessed the good old handicrafts that make me feel the warmth of people at the site, which is like an extension of the old town factory .

Although there are no large-scale automation facilities or large-scale production lines, each Noble Note is made through the collaborative work of "people" with reliable technology and machines .

He also jokingly said, "In reality, we are slaves to machines." "Machine-sama, please move in a good mood."

When I listen to such stories, I can feel something human in the expression of the well-used machine.

The noble notebook “Hatsuyuki”, which was made with all our heart at this place, is now on sale at the Hachimonjiya store and online store! (Mr. Yamada also said, "I've made a lot of things, but this one is cool and I'm excited!")

Bonus ~ Building Appearance

A distribution center nestled in downtown Tokyo.

By relocating the head office this year, bookbinding, distribution, warehousing, and administrative functions have been consolidated.

Everything about that life is here...!

A familiar logo! Monochromatic is often seen, but the vivid two-tone of red and blue was uplifting.

(Text and photo by Nagaoka)